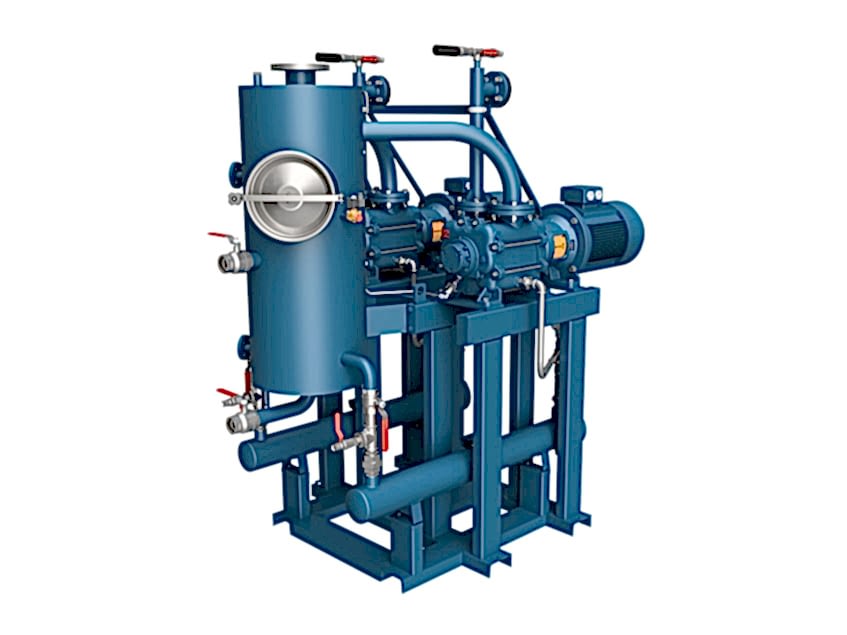

Travaini Travaini HYDROSYS Vacuum Skid

Functioning

The vacuum pump ejects the sucked gas from the delivery port and also part of the service liquid which is present inside it and which must be continuously made up.

The air-liquid mixture is delivered to a cylindric tank where the separation occurs: the gas comes out from the upper delivery port of the tank, ready to be sent again to the vacuum pump.

During the suction and compression cycle, the vacuum pump transfer all the work carried out under the form of heat to the service liquid, which, of course, before being recycled, shall be cooled down either by means of a heat exchanger.

Technical Details

- Applied in industries such as chemical, pharmaceutical, food, oenological, petrochemical etc.

- Vacuum/compression complete package with full recovery of service water.

- Variety of service liquids may be utilised. Minimum losses of service liquid.

- Variety of materials of construction available.

- No contamination of cooling water.

- Shut-off vacuum < 10 mbar (with air ejector).

- Turn key and compact packages environmentally safe.

- Rugged construction with maximum dependability.

- Multiple accessories are available to meet particular plant, process and maintenance needs. Special custom engineered systems can also be studied.

- The HydroSys series can also be used in operation as a compressor up to a maximum pressure of 2 bar higher than the suction pressure by adopting tanks and accessories that meet current standards.

- Capacity up to 3500 m3/h and head up to 33 mbar.

Mail İle Bizimle İletişime Geçebeilirsiniz

Mail İle Bizimle İletişime Geçebeilirsiniz Telefon İle Bizimle İletişime Geçebeilirsiniz

Telefon İle Bizimle İletişime Geçebeilirsiniz